Subsea Diamond Wire Saw

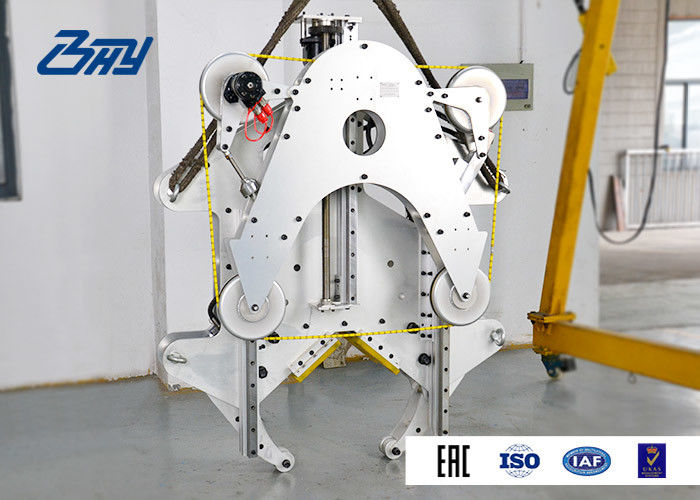

The first dedicated all electric subsea diamond wire saw designed as response tool in water depths of up to 3000 msw.

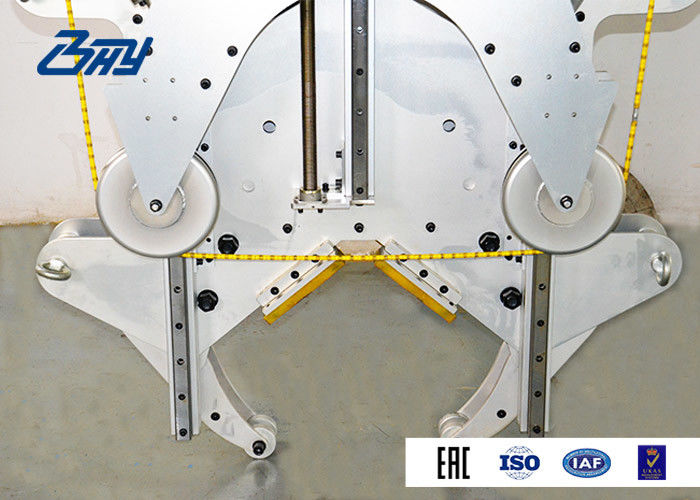

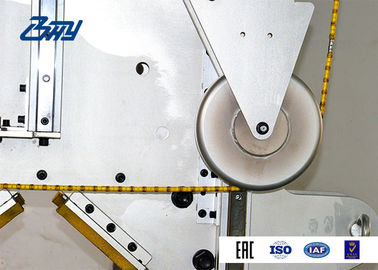

Subsea diamond wire saw. The compact and robust design creates an ideal cutting environment reducing setup installation and removal time saving you time and money. Diamond wire saw dws subsea cutters download letter azshara brochures our brochures section allows users to read more in depth about our specialized tools and services that span several industries such as the offshore energy industry defense entertainment material handling aerospace science and renewable energy industries. Diamond wire saws are ideal for cutting multi string applications or heavy wall legs and cross members. Gsi s saws offer minimal setup and installation time remote operation and overall reduced cutting time and manpower needs versus conventional cutting tools.

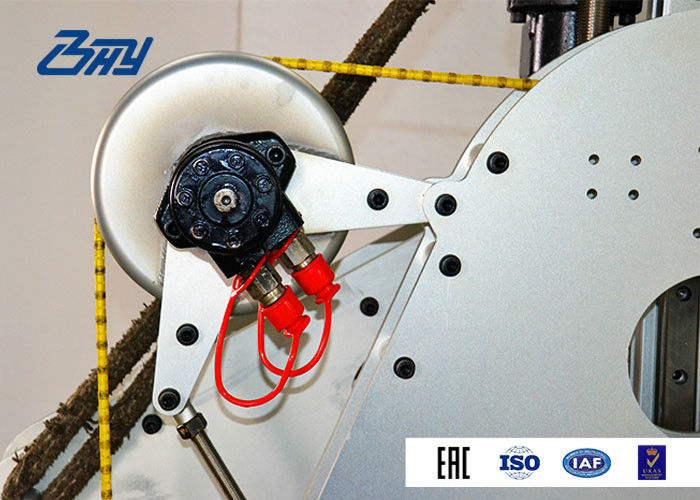

Jfo s hydraulic diamond wire cutting equipment excels in performance safety durability and ease of use. Each diamond wire saw. The mdws620 diamond wire saw is for subsea cutting of pipelines multistring casings piles platform legs wellheads up to 20 diameter. During the development of this saw two criteria were of paramount importance.

The band saw range delivers a cost effective solution to cold cutting requirements in either surface or subsea situations and our diamond wire saws are ideal for quickly cutting through dissimilar materials. The barracuda is a response tool that was specifically designed for subsea cutting in emergency situations. The mirage diamond wire saw mdws is designed for underwater cutting on multistring casings piles platform legs and wellhead. The diamond wire cut is ideal for quick cutting through dissimilar materials and resisting compressive forces.

Typical uses include offshore decommissioning and subsea or topside maintenance. The mirage bolt saw provides an effective solution for cutting seized flange bolts across a wide range of flange diameters.