Storage Tank Heating Coil Calculation

Revised syllabus ce 2016 10 jul 2015.

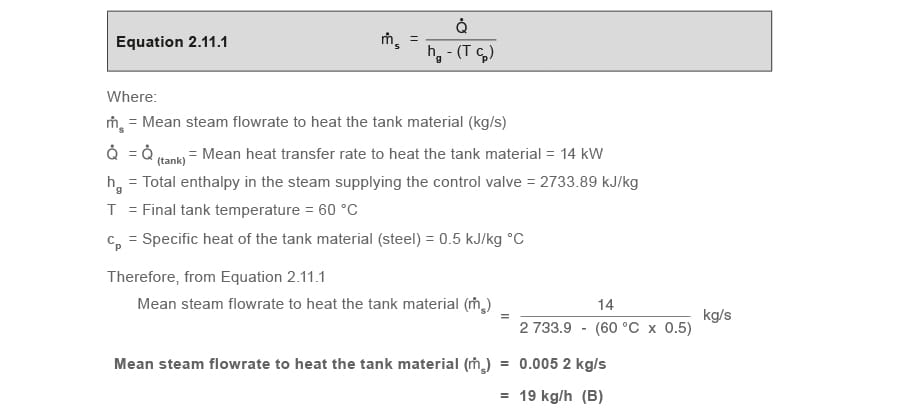

Storage tank heating coil calculation. Carousel previous carousel next. Crude oil storage tank heating coil. More from ahmed mujtaba. To determine kw required to raise the temperature of any liquid complete the fields below.

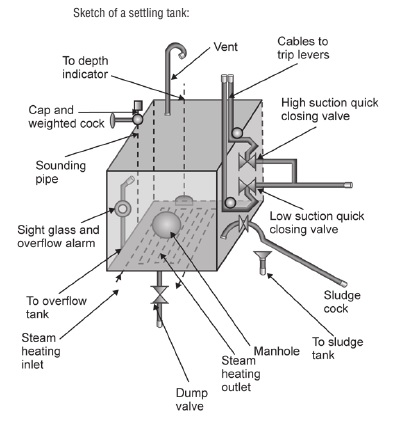

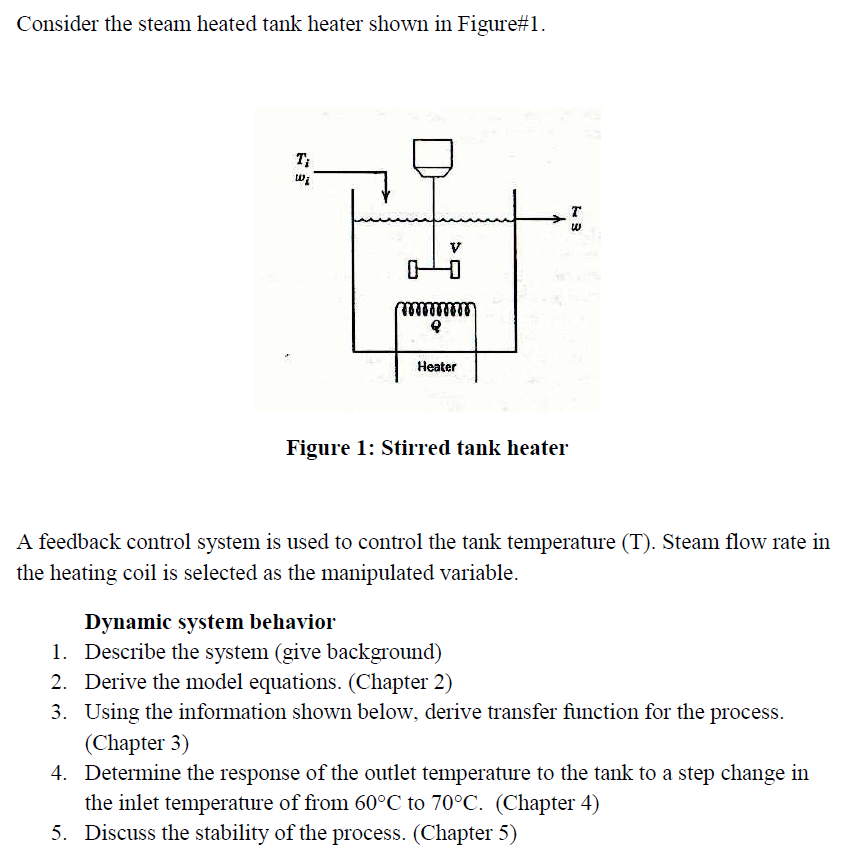

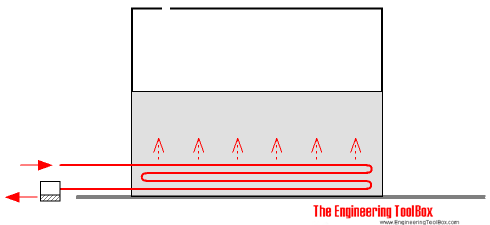

In sizing heat transfer coils it is important to select the configuration with the smallest width and longest length compatible with tank size to provide the best heat distribution. Multiple pipes are provided as required. This calculation does not allow for heat losses. For heat loss calculation and add losses with heat up requirements.

Area a m cm u θ ln t1 t1 t1 t2 heating coil details. Do not alter fields marked in red. Kw liquid tank heating. The open coil heating element can be replaced without draining the tank.

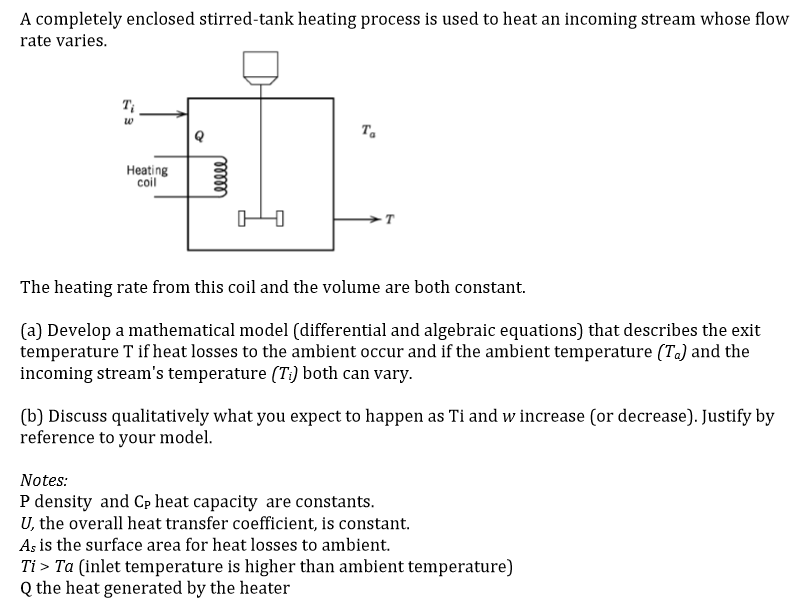

For heating a batch with an internal coil with an isothermal heating medium following equation is applied. The surface area of the coil can be calculated by multiplying the pipe circumference with pipe length as a π 0 0603 m 10 m 1 89 m2. Appendix d emergency response plan. In very long coils such as those sometimes found in seagoing tankers or in large bulk storage tanks a significant pressure drop occurs along the length of the coil.

A sample calculation regarding coils is included tanks constitute important equipment in the chemical process industries cpi. The heater is mounted to the tank by one of three methods. Generally increasing the temperature lowers the viscosity resulting in ease of pumping. Using data found in table v you can determine that a coil width of 18 5 inches and a length of 48 inches provides 13 2 sq ft of surface area.

Various types of liquids are stored in tanks and often these liquids are difficult to handle due to their high viscosities.